Ultrafine Industrial Minerals

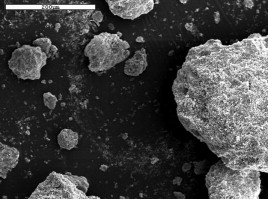

In the world of industrial materials, ultrafine industrial minerals are redefining performance. These finely ground non-metallic minerals — processed to particle sizes typically below 10 microns (µm) — offer enhanced functionality, superior dispersion, and improved product quality across high-tech and consumer industries.

From glossy paints to medical tablets, ultrafine minerals play a quiet but vital role in modern manufacturing.

What Are Ultrafine Industrial Minerals?

Ultrafine industrial minerals are natural inorganic materials that have been mechanically or chemically ground to extremely small particle sizes — often ranging from 0.1 to 10 micrometers (microns) .

At this scale, their surface area increases dramatically , enhancing reactivity, brightness, smoothness, and compatibility with other materials.

These minerals are also known as:

- Micronized minerals

- Sub-micron powders

- Nanofilled particles (in advanced applications)

Common Types of Ultrafine Minerals

| Calcium Carbonate (GCC & PCC) | 0.5–3 µm | High brightness, low abrasion, pH buffering |

| Talc | 1–8 µm | Lamellar structure, lubricity, chemical inertness |

| Kaolin (Calcined & Air-Floated) | 0.3–5 µm | High opacity, good dispersion, thermal stability |

| Silica (Precipitated & Fumed) | 5–40 nm to 2 µm | Reinforcement, thickening, anti-caking |

| Barium Sulfate (Barytes) | 0.2–5 µm | High density, X-ray opacity, chemical resistance |

| Aluminum Trihydrate (ATH) | 1–15 µm | Flame retardant, smoke suppressant |

These are available in both dry powder and slurry forms , depending on application needs.

How Are Ultrafine Minerals Produced?

Producing ultrafine powders requires advanced processing technologies:

1. Dry Grinding

- Equipment: Jet mills, hammer mills, fluidized bed opposed jet mills

- Used for: Talc, calcium carbonate, kaolin

- Advantage: No moisture, suitable for heat-sensitive materials

2. Wet Grinding & Classification

- Equipment: Ball mills, bead mills, hydrocyclones

- Used for: High-purity slurries in paper, ceramics, electronics

- Advantage: Tighter particle size control

3. Surface Treatment

Many ultrafine minerals are coated with stearates, silanes, or titanates to:

- Improve dispersion in polymers

- Reduce agglomeration

- Enhance compatibility with resins or binders

Key Applications Across Industries

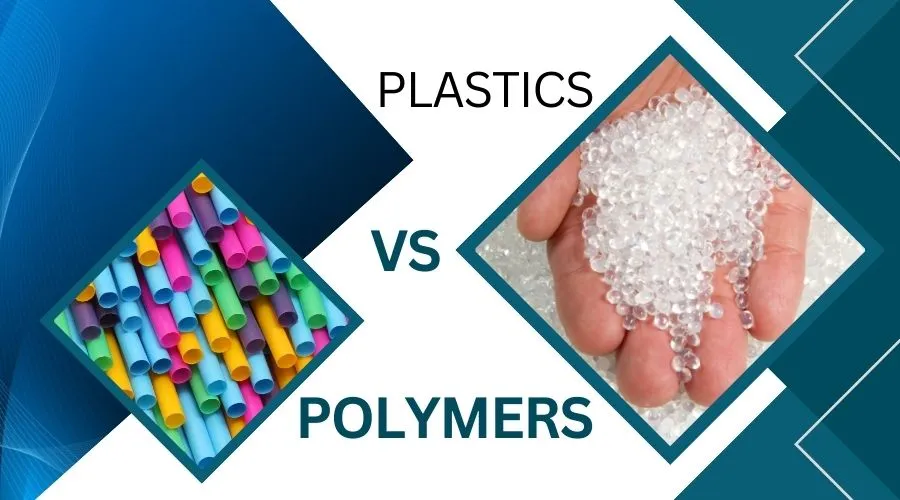

1. Plastics & Polymers

✅ Benefits:

- Improved tensile strength and impact resistance

- Better surface finish and gloss

- Cost reduction by replacing more expensive resins

Used in: PVC pipes, automotive parts, packaging films

2. Coatings & Paints

Ultrafine talc and kaolin improve:

- Scratch resistance

- Matt finish control

- Suspension stability

Highly valued in architectural paints, primers, and industrial coatings .

3. Pharmaceuticals & Cosmetics

Suggested Image:

A cosmetic compact or tablet press machine using mineral fillers.

✅ Examples:

- Magnesium stearate (lubricant in tablets)

- Talc in face powders and lotions (smooth texture)

- Calcium phosphate as a binder in pills

Must meet pharma-grade purity standards (USP/NF, EP).

4. Paper & Board

Ultrafine kaolin and calcium carbonate are used as:

- Coating pigments for high-gloss paper

- Fillers to improve printability and opacity

Critical for premium printing and packaging grades.

5. Advanced Manufacturing & Electronics

- Fumed silica acts as a thickener in encapsulants and adhesives

- Ultrafine barite is used in X-ray shielding materials

- Nano-clays enhance barrier properties in food packaging

Growing demand in EV batteries, semiconductors, and composites

Why Choose Ultrafine Over Standard Grades?

| 🌟Improved Performance | Enhanced mechanical, optical, and rheological properties |

| 🧪Better Dispersion | Uniform distribution in matrices like resin or paint |

| 💰Cost Efficiency | Less material needed for same effect; reduces waste |

| 🔬Enables Innovation | Makes possible new formulations in nanocomposites and smart materials |

Final Thoughts

Ultrafine industrial minerals are not just smaller versions of bulk minerals — they are engineered materials that unlock new levels of performance. As industries push toward lighter, stronger, and smarter products, the demand for these precision-engineered powders will continue to grow.

From automotive interiors to life-saving medications , ultrafine minerals are making modern innovation possible — one micron at a time.

Frequently Asked Questions (FAQs)

Q1: What does “ultrafine” mean in industrial minerals?

A: It refers to particles generally below 10 microns in size , offering increased surface area and improved functional properties.

Q2: Are ultrafine minerals safe to use?

A: Yes, when handled properly. However, fine dust can pose inhalation risks — use PPE and proper ventilation during handling.

Q3: Can I use ultrafine minerals in food or medical products?

A: Only if they are certified food-grade or pharma-compliant (e.g., USP, FCC, EFSA approved). Always verify documentation before use.

Final Tip:

When sourcing ultrafine minerals, always request a Certificate of Analysis (COA) including particle size distribution (PSD), brightness, and impurity levels to ensure batch consistency and suitability for your application.