Lithium Mineral Processing

Lithium mineral processing refers to the series of steps used to extract lithium from naturally occurring lithium-bearing minerals such as spodumene, lepidolite, and petalite, or from brine and clay deposits. The end goal is to produce lithium carbonate or lithium hydroxide, which are essential for manufacturing lithium-ion batteries used in electric vehicles (EVs), energy storage systems, and consumer electronics.

Here’s a breakdown of the key stages in lithium mineral processing.

1. Lithium Sources and Initial Processing

Lithium comes from several types of deposits, each requiring different processing methods:

- Hard Rock (Pegmatite): Lithium is extracted from minerals like spodumene through crushing, flotation, roasting, and acid leaching.

- Brine Deposits: Lithium is concentrated through solar evaporation ponds, then purified into lithium carbonate or hydroxide.

- Clay Deposits: Lithium is extracted using acid leaching, ion exchange, or Direct Lithium Extraction (DLE) methods.

Each source has unique processing challenges and costs.

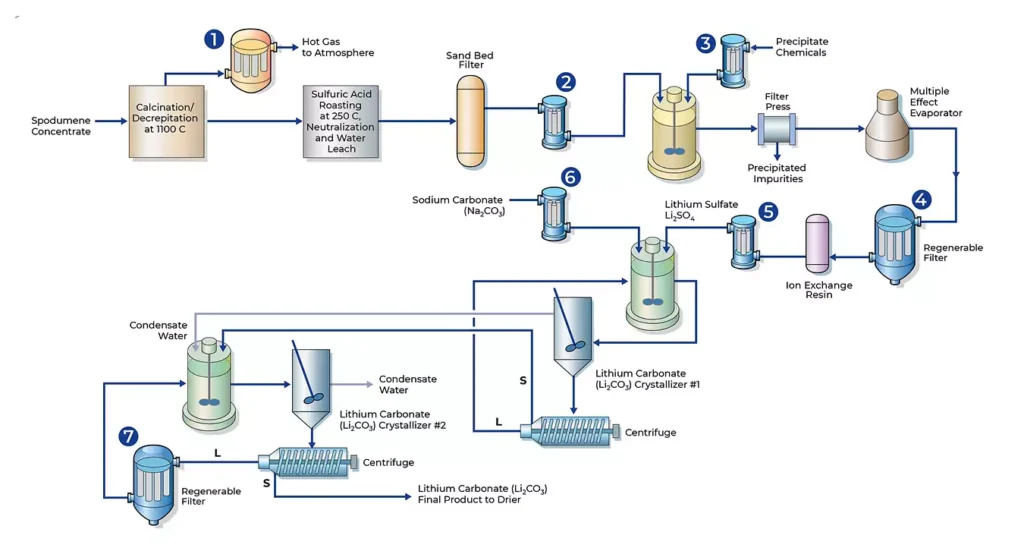

2. Hard Rock Lithium Processing (Spodumene)

Hard rock lithium is primarily extracted from spodumene, a lithium-bearing silicate mineral found in granitic pegmatites.

Key Steps in Hard Rock Lithium Processing:

- Crushing and Grinding: Ore is crushed and ground into fine particles to liberate lithium minerals.

- Flotation: Spodumene is separated from waste rock using froth flotation, where it attaches to air bubbles and is skimmed off.

- Roasting: The spodumene is calcined at high temperatures (around 1,100°C) to convert it from alpha to beta phase, making it easier to process.

- Acid Leaching: Roasted spodumene is treated with sulfuric acid to produce lithium sulfate in solution.

- Purification and Conversion: The solution is purified and treated with sodium carbonate or lime to produce lithium carbonate or lithium hydroxide.

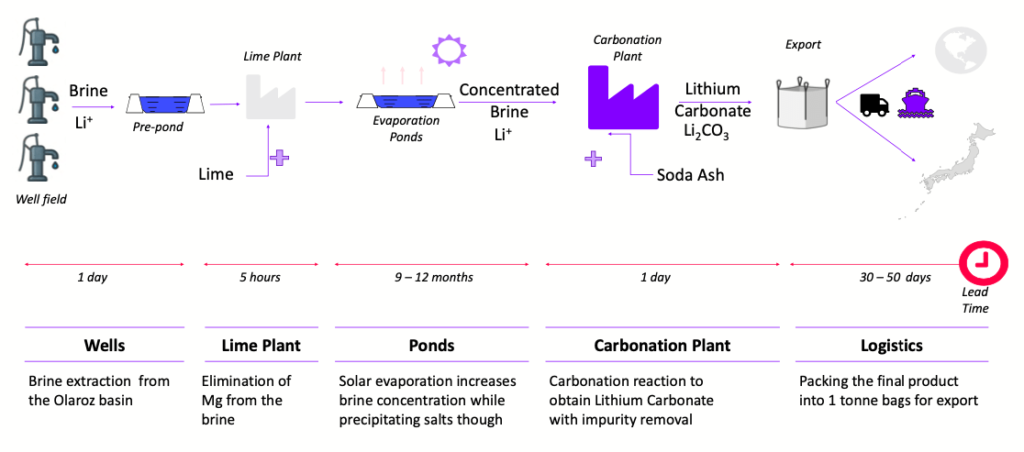

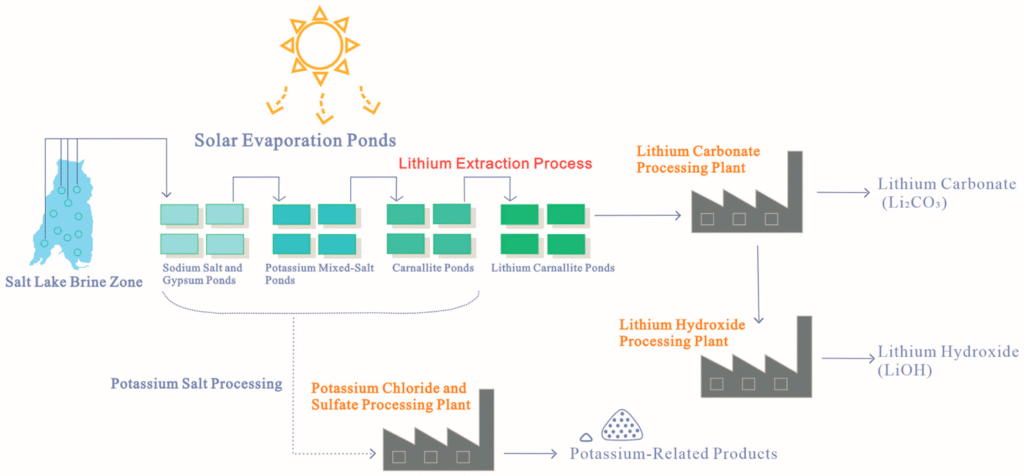

3. Lithium Brine Processing

Brine lithium is extracted from salt-rich underground waters, particularly in salt flats (salars) such as those in Chile and Argentina.

Key Steps in Brine Lithium Processing:

- Pumping: Lithium-rich brine is pumped from underground reservoirs.

- Solar Evaporation: Brine is placed in large ponds where water evaporates over 12–18 months, concentrating the lithium.

- Impurity Removal: Magnesium and other impurities are removed using chemical precipitation or ion exchange.

- Precipitation or Electrowinning: Lithium is precipitated as lithium carbonate, or in newer systems, extracted directly using DLE (Direct Lithium Extraction).

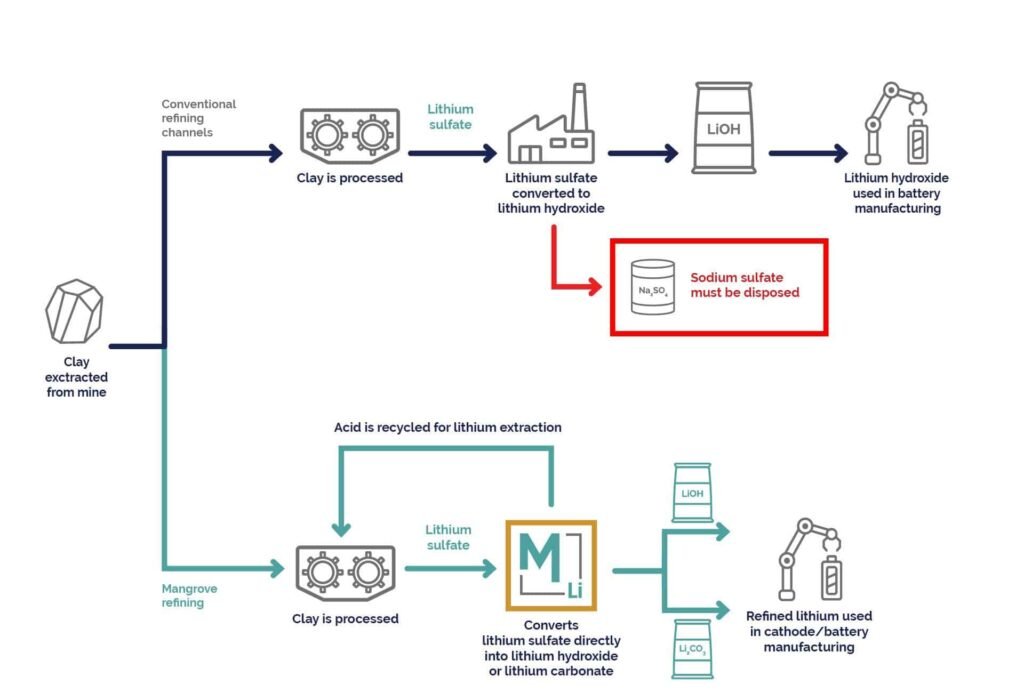

4. Lithium Clay Processing

Clay deposits, such as those found in Nevada (USA) and Serbia, are an emerging source of lithium. Lithium is adsorbed onto clay minerals and must be extracted using chemical methods.

Common Clay Lithium Processing Steps:

- Mining: Lithium-rich clay is extracted through open-pit mining.

- Leaching: Clay is treated with acid or other solvents to release lithium ions.

- Purification: Impurities like iron and aluminum are removed using precipitation or filtration.

- Conversion: The purified lithium solution is converted into lithium carbonate or hydroxide for battery use.

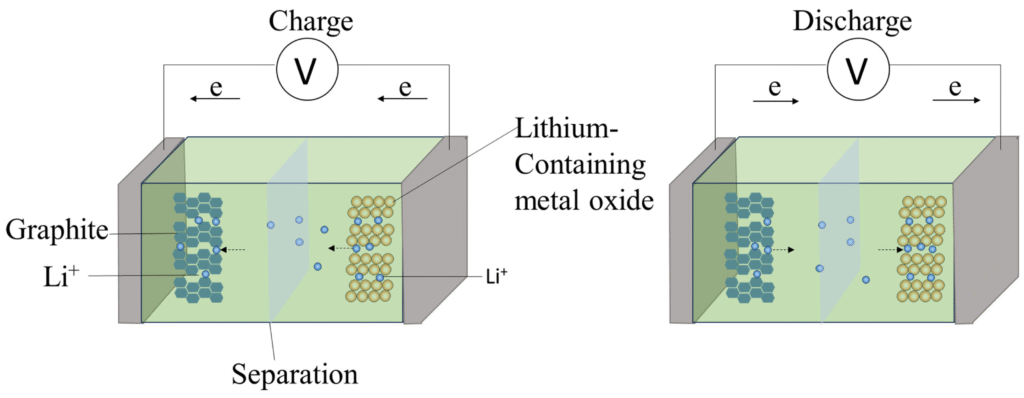

5. Producing Battery-Grade Lithium

The final product of lithium processing is either:

- Lithium Carbonate (Li₂CO₃): Used in LFP (lithium iron phosphate) batteries and ceramics

- Lithium Hydroxide (LiOH): Preferred for NCM (nickel-cobalt-manganese) and NCA (nickel-cobalt-aluminum) cathode chemistries in EV batteries

These compounds are then used by battery manufacturers to produce cathode materials like NMC and LFP.

6. Environmental and Economic Considerations

Lithium processing has environmental and economic implications depending on the source:

- Hard Rock Mining: Generates waste rock and tailings, but allows for high-purity lithium extraction

- Brine Extraction: Low-cost but water-intensive, especially in arid regions

- Clay Extraction: Offers faster extraction times and lower water use with the right technology

New technologies like Direct Lithium Extraction (DLE) are being developed to reduce environmental impact and increase efficiency.

FAQs

Q1: What is lithium mineral processing?

A1: It is the series of steps used to extract lithium from minerals like spodumene or from brines and clays, resulting in lithium carbonate or hydroxide.

Q2: How is lithium extracted from spodumene?

A2: Through crushing, flotation, roasting, acid leaching, and chemical conversion into battery-grade lithium compounds.

Q3: What is Direct Lithium Extraction (DLE)?

A3: DLE is a newer method that allows for faster and more sustainable lithium recovery from brines and clays, without relying on evaporation ponds.

Conclusion

Lithium mineral processing is a critical link in the supply chain that connects raw lithium resources to the clean energy and EV revolution. Whether from hard rock, brines, or clays, the goal is to produce high-purity lithium compounds that power the future of mobility and energy storage.

As technology evolves, more sustainable and efficient processing methods are being developed to meet growing demand while reducing environmental impact.