Industrial Minerals UK

The United Kingdom has a long-standing tradition in geology, mining, and materials science — and at the heart of its modern industrial economy lies the industrial minerals sector . From limestone quarries in Derbyshire to kaolin pits in Cornwall, industrial minerals UK play a vital role in supporting construction, manufacturing, agriculture, and green technology .

These non-metallic, non-fuel minerals may not grab headlines like oil or lithium, but they are indispensable to everyday life — found in concrete, glass, ceramics, paints, plastics, and even toothpaste.

🏗️ Key Industrial Minerals Mined and Used in the UK

While the UK no longer dominates global mineral production as it once did during the Industrial Revolution, it remains a significant producer and user of high-value industrial minerals:

| Limestone & Calcium Carbonate | Peak District, Yorkshire, Scotland | Cement, aggregates, flue gas desulfurization |

| Kaolin (China Clay) | Cornwall | Ceramics, paper coating, pharmaceuticals |

| Ball Clay | Dorset & Devon | High-quality ceramics and sanitaryware |

| Silica Sand | Cheshire, Northumberland | Glassmaking, foundry casting, fracking proppant |

| Barytes (Barite) | Scotland (Glenshee), Northern Ireland | Drilling muds, radiation shielding |

| Talc | Luzenac Group operations (formerly Trimouns UK) | Plastics, cosmetics, paints |

| Gypsum | Evaporite deposits & FGD byproduct | Drywall, plaster, cement retarder |

Many of these minerals are sourced from active quarries and processed to meet strict British and EU standards.

⚙️ Major Applications Across UK Industries

Industrial minerals are embedded in nearly every aspect of the UK’s economy:

1. Construction & Infrastructure

- Limestone and crushed rock supply over 80% of aggregates used in roads, buildings, and rail projects.

- Gypsum from natural deposits and flue gas desulfurization (FGD) powers the drywall industry.

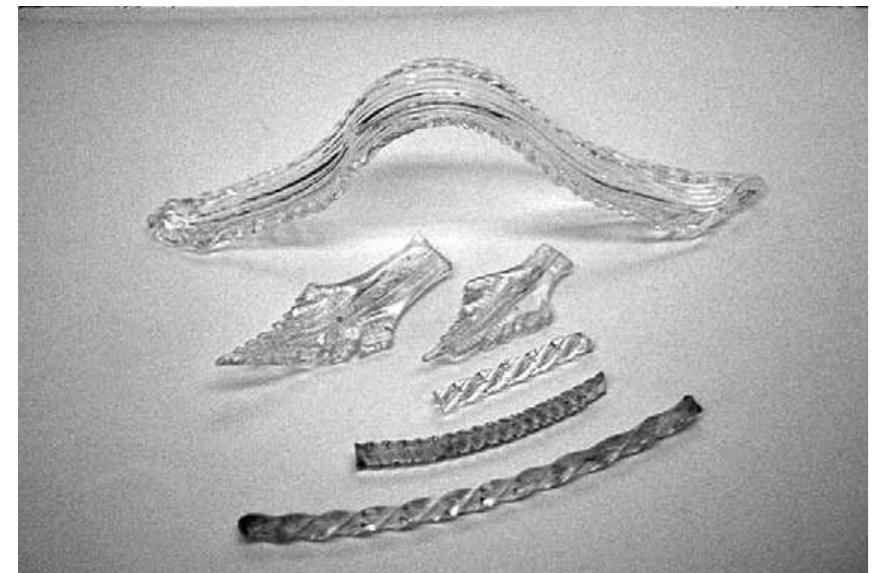

2. Manufacturing & Advanced Materials

- Kaolin and ball clay from Cornwall and Devon are world-renowned for producing premium ceramics.

- Micronized calcium carbonate enhances performance in paints, adhesives, and polymer composites.

3. Energy & Oil & Gas

- Barytes from Scottish mines is milled into API-grade powder for offshore drilling fluids in the North Sea.

- Silica sand supports hydraulic fracturing trials and geothermal exploration.

4. Agriculture & Environment

- Ground limestone and dolomite are widely used to neutralize acidic soils in farming regions across Wales, Scotland, and Northern England.

- Calcined clays are emerging as low-carbon alternatives in cement production .

🌱 Sustainability and Future Trends

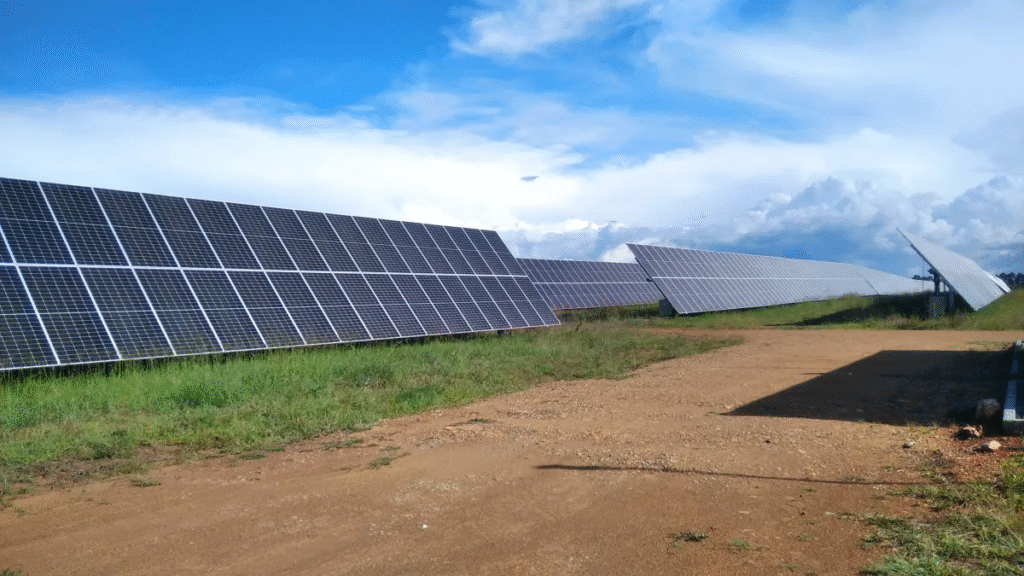

The UK government’s push toward net-zero emissions by 2050 is reshaping the industrial minerals landscape:

- Carbon Capture Use & Storage (CCUS): Minerals like olivine and basalt are being studied for mineral carbonation.

- Circular Economy: Recycled gypsum from demolition waste now accounts for up to 30% of drywall.

- Critical Raw Materials Strategy: The UK is assessing domestic supplies of minerals essential for EVs, wind turbines, and digital tech — including industrial co-products.

Additionally, stricter planning regulations ensure that new quarrying projects include land restoration plans and community benefits.

❓ Frequently Asked Questions (FAQs)

Q: Where are industrial minerals mined in the UK?

A: Major sites include limestone quarries in the Peak District, kaolin pits in Cornwall, barytes in Scotland, and silica sand in Cheshire and Northumberland.

Q: Is the UK self-sufficient in industrial minerals?

A: For many minerals like limestone, gypsum, and kaolin, yes — but some high-purity grades (e.g., ultrafine talc or specialty barite) are imported to meet demand.

Q: How is the UK making industrial minerals more sustainable?

A: Through recycling (e.g., gypsum), land reclamation, low-emission processing, and research into carbon-absorbing minerals.