Industrial Minerals & Refractories

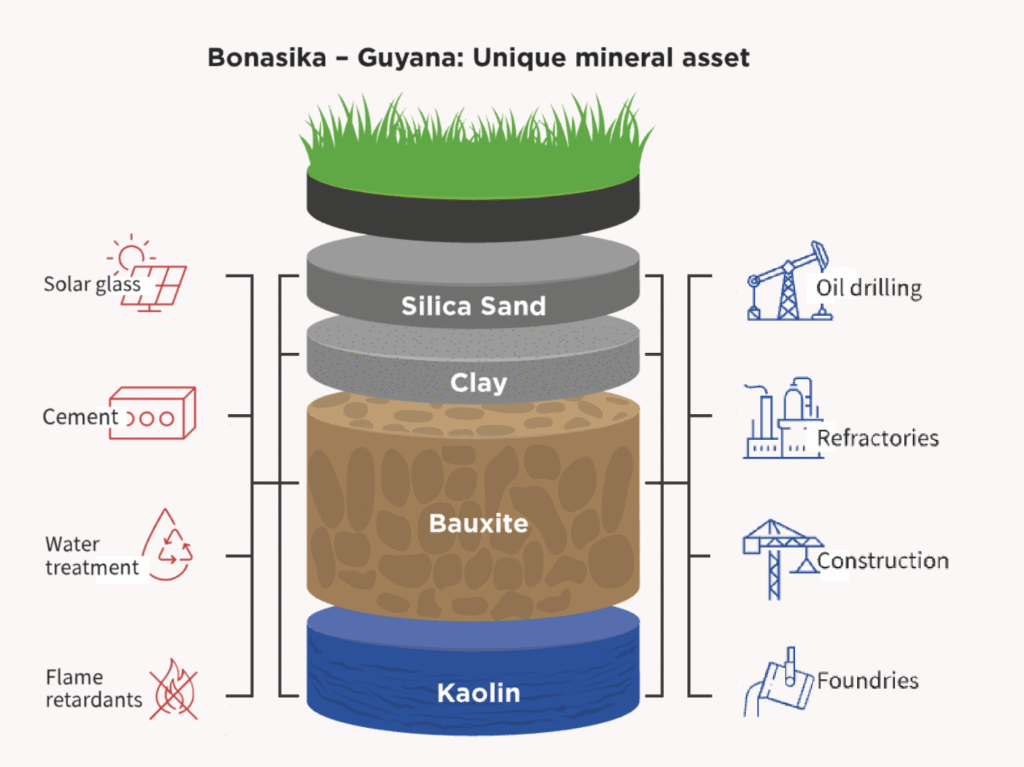

In the world of heavy industry, few materials are as essential as industrial minerals and refractories . These specialized substances form the backbone of high-temperature applications in sectors such as steelmaking, cement production, glass manufacturing, petrochemical refining, and ceramics .

Understanding the connection between industrial minerals — the raw natural resources — and refractories — the engineered products made from them — is key to ensuring efficiency, safety, and durability in extreme environments.

🧱 What Are Industrial Minerals?

Industrial minerals are naturally occurring, non-metallic minerals used for their physical and chemical properties rather than for metal extraction or fuel value.

Common examples include:

- Kaolin (clay)

- Bauxite

- Silica (quartz)

- Magnesite

- Dolomite

- Talc

- Feldspar

These minerals serve as primary feedstocks for producing refractory materials due to their heat resistance, low thermal expansion, and chemical stability.

🔥 What Are Refractories?

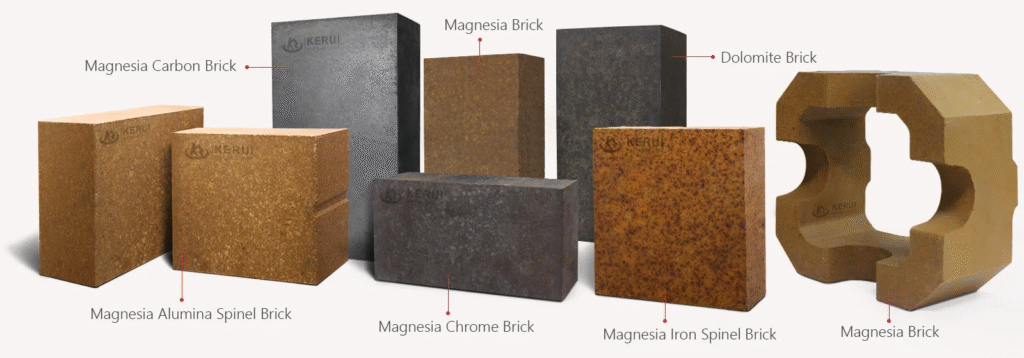

Refractories are heat-resistant materials designed to withstand extreme temperatures (up to 1,800°C+) , thermal shock, corrosion, and mechanical stress. They line industrial furnaces, kilns, reactors, and incinerators to protect equipment and maintain process efficiency.

Refractories are classified into three main types:

| Alumina-Silica | Kaolin, fireclay, silica | Steel ladles, boilers, glass tanks |

| Basic (Magnesia-Based) | Magnesite, dolomite | Steel converters, cement kilns |

| Specialty | Zirconia, silicon carbide | Aerospace, advanced ceramics |

These are available in shaped (bricks) and unshaped (castables, gunning mixes) forms.

⚙️ How Industrial Minerals Enable Refractory Performance

The quality of refractories depends directly on the purity, grain size, and composition of the industrial minerals used:

- Kaolin & Fireclay : Provide excellent thermal shock resistance — ideal for boiler linings.

- Bauxite (high-alumina) : Offers superior strength and slag resistance in steel plants.

- Silica : Used in acidic environments like glass melting tanks.

- Magnesite : Resists basic slags in oxygen converters and electric arc furnaces.

- Dolomite : An affordable alternative to magnesia in cement kiln linings.

By selecting the right mineral base, manufacturers can tailor refractories for specific temperature ranges, chemical exposures, and mechanical demands.

❓ Frequently Asked Questions (FAQs)

Q: What is the relationship between industrial minerals and refractories?

A: Industrial minerals like bauxite, kaolin, and magnesite are the raw materials used to manufacture refractory products that resist high heat and corrosion in industrial processes.

Q: Where are refractories used in industry?

A: They are essential in steelmaking furnaces, cement kilns, glass tanks, petrochemical crackers, and power plant boilers — wherever extreme heat is involved.

Q: Why are high-purity industrial minerals important for refractories?

A: Higher purity improves melting point, structural integrity, and resistance to slag and thermal cycling — extending furnace life and reducing downtime.