Industrial Minerals: Garnet

While garnet is best known as a gemstone, it’s also a highly valuable industrial mineral prized for its hardness, durability, and natural inertness .

In industrial applications, almandine and pyrope — the most common types of industrial garnet — are used across a wide range of sectors, from manufacturing to water treatment.

What Is Industrial Garnet?

Industrial garnet is a naturally occurring silicate mineral that is mined and processed for use in abrasive blasting, waterjet cutting, and filtration systems . Unlike synthetic abrasives, garnet is eco-friendly, non-toxic , and highly effective in precision applications.

Garnet scores between 7 and 7.5 on the Mohs hardness scale , making it harder than steel and suitable for aggressive cutting and grinding tasks.

Key Industrial Applications of Garnet

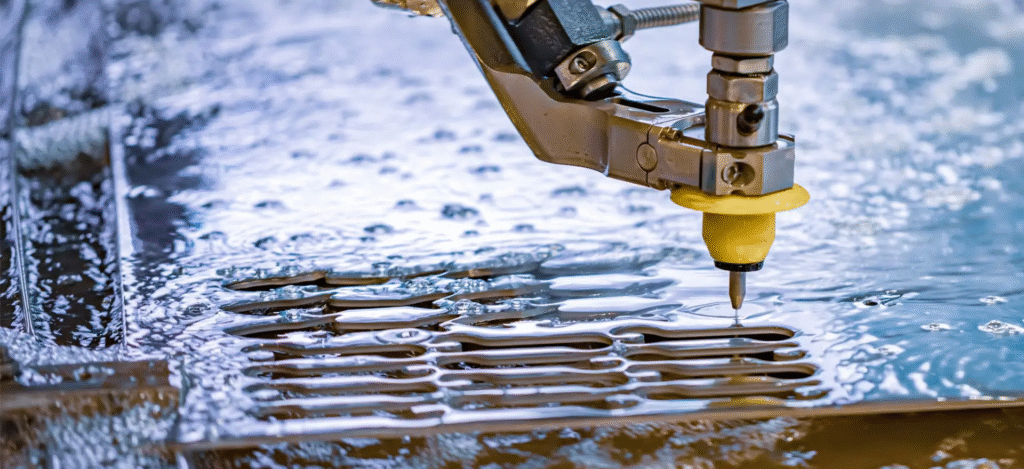

1. Waterjet Cutting

Garnet is the preferred abrasive in high-pressure waterjet cutting systems , used to cut metals, stone, glass, and composites with precision and minimal heat damage .

- Industries : Aerospace, automotive, metal fabrication

2. Abrasive Blasting

Garnet is used in sandblasting and surface preparation , especially in marine and industrial coating removal.

- Advantages : Low dust generation, recyclable, and environmentally safe

3. Filtration Media

Due to its high density and angular structure , garnet is used in multi-media water filters for municipal and industrial water treatment.

- Benefits : Traps fine particles, longer filter life, improved water quality

4. Non-Slip Flooring and Traction Control

Garnet is used in anti-slip coatings for walkways, stairs, and industrial floors.

Why Choose Garnet as an Industrial Mineral?

- Natural and Sustainable : Garnet is a naturally occurring mineral with minimal processing.

- High Performance : Excellent cutting ability, consistent particle size, and low dust generation.

- Eco-Friendly : Non-toxic and safe for use in food processing, water treatment, and marine environments.

- Cost-Effective : Reduces equipment wear and offers better performance than many synthetic abrasives.

With increasing emphasis on green technologies and sustainable materials , garnet is becoming even more valuable in industrial applications.

Frequently Asked Questions (FAQs)

Q1: What types of garnet are used in industry?

A: The most commonly used types are almandine and pyrope , known for their hardness and abrasive qualities.

Q2: Is garnet better than other abrasives like aluminum oxide or silica sand?

A: Garnet is often preferred due to its natural origin, low dust, and superior cutting performance , especially in waterjet applications.

Q3: Can industrial garnet be recycled?

A: Yes, garnet can often be reused multiple times in abrasive blasting and waterjet applications before needing replacement.