Mining Chemicals in South Africa

Mining Chemicals in South Africa: The Backbone of Mineral Processing

Mining chemicals play a pivotal role in the extraction, processing, and refining of minerals in South Africa’s mining industry. These specialized chemicals are essential for enhancing efficiency, improving recovery rates, and minimizing environmental impacts during mineral processing. From gold leaching to flotation reagents and tailings management, mining chemicals are integral to South Africa’s position as a global leader in mineral production. In this blog post, we will explore the significance of mining chemicals, their applications, key players in the industry, and the challenges and opportunities associated with their use.

The Role of Mining Chemicals in Mineral Processing

Mining chemicals are used at various stages of mineral processing to optimize operations. They include:

- Leaching Agents : Used in gold and copper mining to dissolve metals from ores (e.g., cyanide for gold leaching).

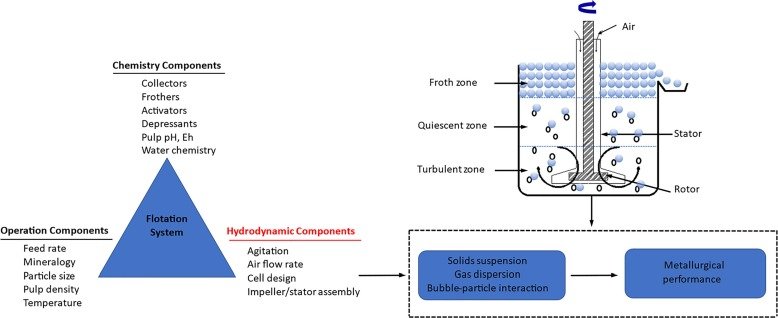

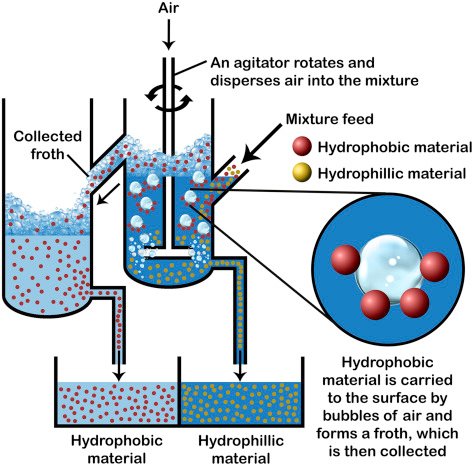

- Flotation Reagents : Facilitate the separation of valuable minerals from waste rock by creating bubbles that carry minerals to the surface.

- Solvents and Extractants : Essential for solvent extraction and electrowinning processes in base metal recovery.

- Tailings Management Chemicals : Help stabilize and neutralize mine waste to reduce environmental risks.

These chemicals ensure efficient resource recovery while addressing safety and sustainability concerns.

Key Applications of Mining Chemicals

1. Gold Mining

In South Africa, gold mining relies heavily on cyanide-based leaching to extract gold from low-grade ores. Advances in eco-friendly alternatives, such as thiosulfate-based leaching, are gaining traction to address environmental concerns.

2. Platinum Group Metals (PGM)

Flotation reagents are critical for concentrating platinum group metals from complex ores. These chemicals selectively bind to PGMs, enabling efficient separation and higher recovery rates.

3. Coal Beneficiation

Mining chemicals are used in coal beneficiation to remove impurities and improve the quality of coal. This ensures compliance with environmental regulations and enhances the market value of coal products.

4. Tailings and Waste Management

Chemicals like flocculants and coagulants are used to treat mine tailings, reducing water contamination and stabilizing waste materials. This is particularly important in South Africa, where historical mining has left significant environmental legacies.

Key Players in South Africa’s Mining Chemicals Industry

Several companies supply mining chemicals to South Africa’s mining sector, offering innovative solutions to meet industry needs:

1. BASF

A global leader in chemical solutions, BASF provides advanced flotation reagents, leaching agents, and tailings management products tailored to South African mines.

2. Nalco Water (Ecolab)

Nalco specializes in water treatment and process optimization, offering chemicals that improve efficiency and reduce environmental impacts in mining operations.

3. Solvay

Solvay supplies a wide range of mining chemicals, including collectors, frothers, and depressants, which are widely used in South Africa’s gold and PGM sectors.

4. Cheminova

Cheminova focuses on developing eco-friendly alternatives to traditional mining chemicals, aligning with South Africa’s push for sustainable practices.

Challenges Facing the Use of Mining Chemicals

1. Environmental Concerns

The use of chemicals like cyanide in gold mining poses significant environmental risks, including water pollution and soil contamination. Developing safer alternatives is a priority.

2. Rising Costs

The cost of mining chemicals has increased due to supply chain disruptions and rising demand. This impacts profitability, especially for smaller mining operations.

3. Regulatory Compliance

Stringent environmental regulations require mining companies to adopt safer and more sustainable chemical practices. Non-compliance can result in fines or operational shutdowns.

4. Limited Awareness of Eco-Friendly Solutions

While eco-friendly alternatives exist, awareness and adoption remain limited. Many mining companies continue to rely on traditional chemicals due to cost or familiarity.

Opportunities for Growth

1. Adoption of Green Technologies

South Africa’s mining industry is increasingly adopting green technologies, including biodegradable reagents and non-toxic leaching agents. This shift presents opportunities for innovation and investment.

2. Research and Development

Investment in R&D can lead to breakthroughs in mining chemical formulations, improving efficiency and reducing environmental impacts.

3. Collaboration with Local Suppliers

Partnering with local chemical suppliers can reduce costs, enhance supply chain resilience, and support domestic industries.

4. Focus on Water Conservation

Mining chemicals that improve water recycling and reduce consumption are in high demand, given South Africa’s water scarcity challenges.

Frequently Asked Questions (FAQs)

Q1: What are mining chemicals?

A1: Mining chemicals are specialized substances used in mineral extraction, processing, and waste management to improve efficiency and recovery rates.

Q2: Why are mining chemicals important in South Africa?

A2: Mining chemicals are crucial for optimizing mineral recovery, reducing environmental impacts, and ensuring compliance with regulations in South Africa’s mining industry.

Q3: What are the environmental impacts of mining chemicals?

A3: Some mining chemicals, like cyanide, can cause water pollution and soil contamination. However, safer alternatives and proper management can mitigate these risks.